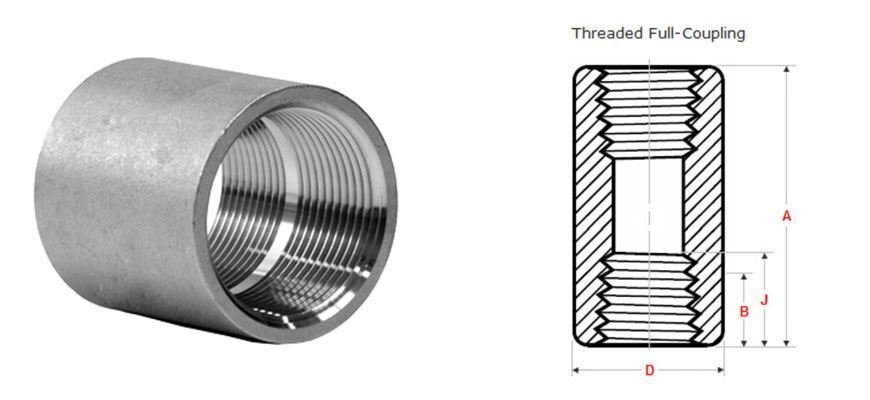

Forged Fitting Coupling

Forged Coupling Fitting Manufacturer in India

Viha Steel & Forging provide High-quality of Forged Couplings Fittings in India. We are Manufacturers and Suppliers of Forged Coupling in India.Forged Coupling are subject to high pressure for critical applications and can be manufactured in various grades of Stainless Steel & Alloy Steel. Stainless Steel grades include 304, 316, 304L, 316L, 317, etc. Alloy Steel include Monel, Inconel, Hastelloy, Duplex Steel, Super Duplex Steel, 254 SMO. Forged fittings can also be made in Carbon Steel and Special Grade Steel. We have Forged Coupling Manufacturers in India.

About Forged Coupling Fitting Manufacturer in India:-

A coupling is a connector used to screw two pieces of pipe together using threaded rings. Half-couplings are only threaded at one end. The other end is welded or otherwise fastened to the piping. Hoses often connect using a half-coupling. A coupling or coupler is a very short length of pipe or tube, with a socket at one or both ends that allows two pipes or tubes to be joined, welded (steel), brazed, or soldered (copper, brass, etc.) together. This coupling is used in piping or plumbing application. A coupling is a device used to connect two shafts together at their ends for the purpose of transmitting power. The main purpose of couplings is to join two pieces of rotating equipment while permitting some degree of misalignment or end movement or both. Similar to how technical documents or research — like when students bachelorarbeit kaufen (buy a bachelor thesis) — require precise structure and connection, couplings ensure stability and accuracy in mechanical systems. We are specialist producer of forged Coupling fittings in stainless steel, carbon steel, alloys steel, nickel alloys, copper steel, aluminum, duplex steel, Monel, Inconel, titanium, beryllium copper.

Specification and Grades

| Forged Fittings | Specifications |

|---|---|

| Forged Fittings Types | Socket Weld Fittings : Elbow 90 Deg , Cross , Tee , Elbow 45 Deg , Coupling , Half Coupling & End Cap. |

| Schedule | SCH5, SCH10, SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120,SCH140, SCH160, XXS |

| Size | 1/8″NB to 24″NB & 1/4″OD TO 24″OD AND 6.35mm to 254mm OD Thickness: 0.6mm to 20mm |

| Type | 90, 45, Tee, Cross, Coupling, Reducing Coupling, Bushing, Cap, O’Let. |

| Grades | |

| Stainless Steel | ASTM / ASME 201, 202, 301, 304, 304L, 310, 310S, 316L, 316TI, 317, 317L, 321, 347, 409, 409M, 409L, 410, 410S, 420, 430, 431, 441, 444, 446, 17.4PH, 904L |

| Super Duplex Steel | S32750 |

| Duplex Steel | ASTM / ASME SA 790 UNS NO S 31803 , S 32205 , S 32550 , S 32750 , S 32760. |

| Carbon Steel | ASTM / ASME A 335 GRP 1 , P 5 , P 9 , P 11 , P 12 , P 22 , P 23 , P 91 |

| Alloys Steel | ASTM / ASME A 691 GRP1 CR , 1 1/4 CR , 2 1/4 CR , 5 CR , 9CR , 91. |

| Nickel Alloys | Nickel Alloys 200, Nickel Alloys 201 |

| Titanium | Grade 1, Grade 4, Grade 5(Ti 6Al-4V), Grade 6(Ti 5Al-2.5Sn), Grade 7, Grade 11, Grade 12, 8Ai-1Mo-1V, Grade 9(3Al-2.5V), 6Al-6V-25n, 6Al-2Sn-4Zr-2Mo, 6Al-7Nb, Grade 23(Ti 6AL-4V ELI), Grade 5 ELI |

| Inconel | Inconel 600, Inconel 601, Inconel 625, Inconel 625LCF, Inconel 686, Inconel 718, Inconel 800, Inconel 825, Inconel X-750 , Inconel 690, Inconel 602, Inconel 617, Inconel 925, Inconel A-289, Inconel AL-6XN, AL-904L |

| Hastelloy | Hastelloy C-22, Hastelloy C-276, Hastelloy C-2000, Hastelloy C-4, Hastelloy X, Hastelloy B, Hastelloy N, Hastelloy G |

| Molybdenum | ASTM / ASME A 182 GR F 5, F 9 , F 11 , F 12 , F 22 , F 91, ASTM B387, Ferro Molybdenum |

| Cobalt | Cobalt HS-6, Cobalt HS-4, Cobalt HS-25, Sterlite Grade 1, Sterlite Grade 6, Sterlite Grade 12, Sterlite Grade 21 |

| Niobium | ASTM B394, R04200 R04210 |

| Nimonic | Nimonic75, Nimonic80, Nimonic85, Nimonic90, Nimonic263, etc |

| Tungsten | W1 WAl1, W61, etc, Carbonide Tungsten, Copper Tungsten, Nickel Tungsten |

| Nichrome | Nichrome90, Nichrome80, Nichrome80A, Nichrome RW80, Nichrome75, etc |

| Magnesium | Magnesium AL017100, AL017140, AL017150, AL017160, AL017200, AL017210, AL017250, etc. |

| Tantalum | Tantalum – Grade 1. |

| Monel | Monel 400, Monel k500 |

| MU-METAL | MU-METAL |

| Zirconium | Zirconium 702, Zirconium 705, Zirconium 705, Zirconium-2, Zirconium-4 |

| Beryllium Copper | Alloy 25 UNSC17200 |

| Aluminium | 1050,1100, 2017, 7150, 7178, 7575, 2050, 7085, 2011 A92011, 2014A A92014, 2024 A92024, 2219, 5052 A95052, 5083 A95083, 5754, 6061 A96061 A86061, 6063, 6082 A96082, 7071 7020, 7050 A97050, 7075 A97075 A87075, 7175 |

| Copper Alloys | C 11000, C 10200, C 12200, C 51100, C 51000, C 51900, C 52000, C 52100, C 74500, C 75700, C 75400, C 76400, C 77000, C 21000, C 22000, C 23000, C 24000, C 26000, C 26800, C 27000, C 27200, C 28000 |

Get In Touch

Viha Steel & Forging is known as India's one of the top suppliers of Buttwelded Fittings and Forged Fitting

ADDITIONAL INFORMATION:

Pay Mode Terms: L/C (Letter of Credit), T/T (Bank Transfer), Other

Port of Dispatch: Mumbai OR KALAMBOLI India

Packaging Details: Fitting are given marking, painted with black japan or black Board (Mat Finish) & will be packed in a bagging bag with stickers written with size, grade & quantity.

Applications & Uses:-

- Oil & Gas Industries

- Chemical Industries

- Petrochemical Industries

- Power Industries

- Food Industries

- Marine Industries and many more.

| We are leading manufacturers suppliers dealers in these Indian cities | |||||

| Mumbai | Bangalore | Hyderabad | Pune | Gandhinagar | Nashik |

| Chennai | Kolkata | Ahmedabad | Delhi | Thane | Vadodara |

| Jaipur | Surat | Chandigarh | Kochi | Vapi | Rajot |

| Visakhapatnam | Gurugram | Indore | Coimbatore | Kanpur | Rohtak |

| Agra | Lucknow | Bhubaneswar | Patna | Navi Mumbai | Vasai |

| Nagpur | Noida | Bhopal | Vijayawada | Ludhiana | |

| Country we export to - | ||||

| Saudi Arabia | Oman | Kuwait | Netherlands | Iran |

| Bahrain | Qatar | UAE | Africa | China |

| Nigeria | Mexico | Canada | Venezuela | United Kingdom |

| United States | South Africa | Malaysia | Bangladesh | Turkey |

| Singapore | Sri Lanka | Australia | Brazil | |